CARBON

CAPTURE IN

LATVIA

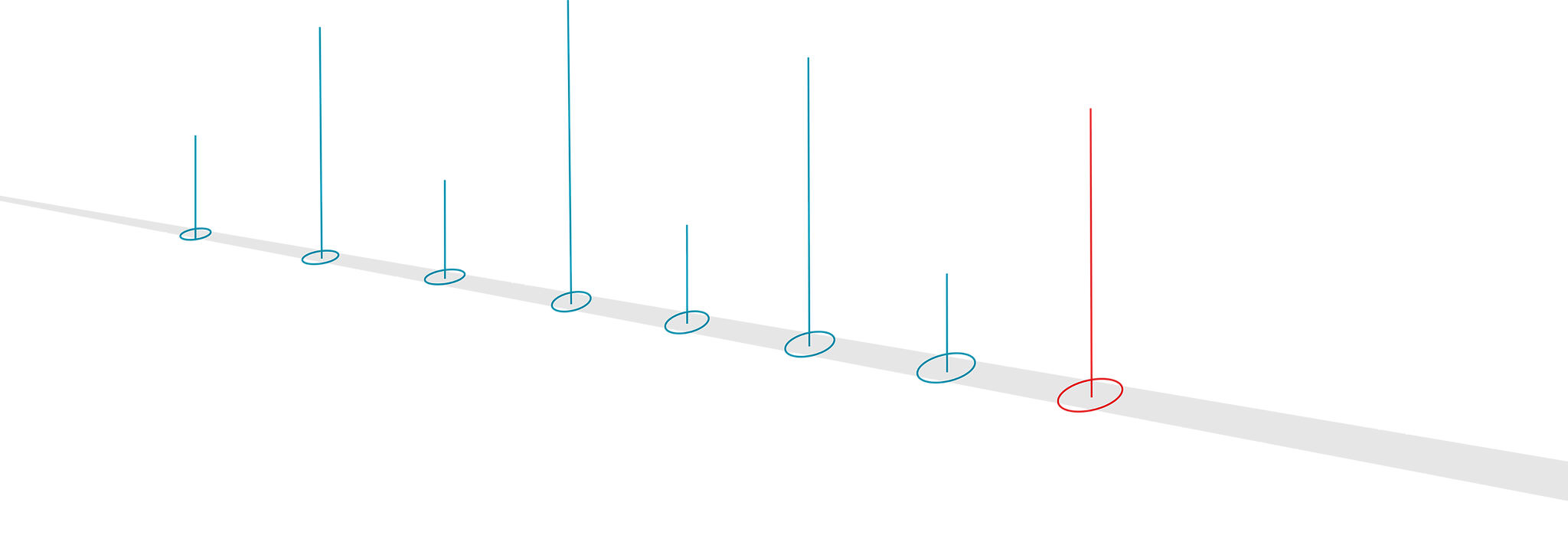

Our way to carbon capture in SCHWENK cement plant in Broceni, Latvia, started in 2019 with setting a clear goal to decarbonize cement production by 2030. With targeted action plan ever since, in 2025 we have reached significant milestone – first carbon capture testing facility with capacity of capturing up to 2 tons of CO2 daily. After extensive feasibility and pre-feed studies, Norwegian company’s Capsol Technologies ASA hot potassium carbonate technology have been chosen as potentially most suitable for the plant specifics. After further research and analysis, the final investment decision is planned to be made in 2027 with full scale carbon capture from 2030.

SCHWENK Group defines carbon capture as one of the three strategic goals towards decarbonization of cement production

Action plan kick-off – analysis of market and geologic storage potential, seeking partnerships and discussions about possible developments of carbon capture

Engagement in the first partnership for further value chain development – CCS Baltic Consortium

Completion of EU Horizon 2020 carbon capture testing and development project GENESIS in Broceni cement plant

CCS Baltic Consortium receives a PCI (Project of Common Interest) status from European Commission

Carbon capture feasibility study and start of pre-FEED studies in Broceni cement plant

Carbon capture technology testing in Broceni cement plant

FEED / Front – end engineering and design studies

Final investment decision

Engineering, procurement and construction contracting

Full scale carbon capture in SCHWENK Latvija cement plant in Broceni